[nextpage title=”Introduction”]

Computer fans are basically brushless motors with blades attached to them in order to move air. They are common-place inside a computer and can be constructed with different technologies. In this tutorial we will be examining one of the components found in fans that is the subject of a lot of confusion, the bearing.

You probably have seen it written several times that the fans used in PCs are “brushless,” but what does that mean? Let’s study first how a motor with brushes works.

Motors with brushes are a piece of metal with a copper wire wrapped around it. This piece of metal is movable and has a shaft attached to it, so whenever it moves, the shaft also moves, spinning whatever is attached to the shaft.

When energized, this piece of metal is transformed into an electromagnet, generating a magnetic field with two poles (labeled north and south). Around the motor there are two big pieces of curved magnets, one producing a north magnetic field and the other producing a south magnetic field. When the magnetic field generated by the electromagnet is the same as the magnetic field generated by the stationary magnet, the motor will move, because identically labeled magnetic poles repel each other. Also, the magnetic field presented by the opposite magnet will be the opposite, attracting the electromagnet. We illustrate this situation as the “first step” in Figure 1.

However, after the motor moves 180° pushed by the repelling magnetic forces, it will stop, because the system will now be equalized: since the motor spun, now the magnetic fields generated by the motor will be of the opposite type of the magnetic fields generated by the stationary magnets, making the motor to be attracted by the stationary magnets instead of being repelled.

Figure 1: How a motor with brushes works

For the motor to rotate again, the direction of the current applied to the wire must be reversed. By reversing the polarity, the magnetic fields generated by the motor will also be reversed, creating again the same situation we had in the first step, moving the motor 180° on more time. Then it will stop again.

So, for the motor keep continuously rotating, we need a mechanism that will automatically reverse the polarity of the wire right after the motor spins 180°. The easiest and cheapest way to accomplish this is by using a pair of brushes. The ends of the wire that is wrapped around the motor are attached to two contacts (also called “commutators”) and two brushes touch these contacts. The brushes are always set to the same polarity, but since the contacts will move together with the motor the polarity will be reversed whenever the motor spins 180°. We illustrate this in Figure 2.

Figure 2: Brush system

Of course this is an oversimplified explanation, but it should be enough for you to understand the principle behind motors with brushes.

The motors used in computer fans, however, don’t work this way, because motors with brushes are noisy, produce sparks whenever the contacts touch the brushes, wear very fast because of the contact between the commutators and the brushes, and are not very reliable at high speeds.

[nextpage title=”The Brushless Motor”]

Computer fans are more sophisticated, as they use brushless motors. As the name implies, this kind of motor doesn’t use brushes. The design of this kind of motor is a little bit different.As we saw in the previous page, motors with brushes have stationary magnets and the copper-wire windings are wrapped around the rotating part. Brushless motors are constructed the opposite way: the electromagnet (copper-wire coil) is stationary and the magnets rotate.

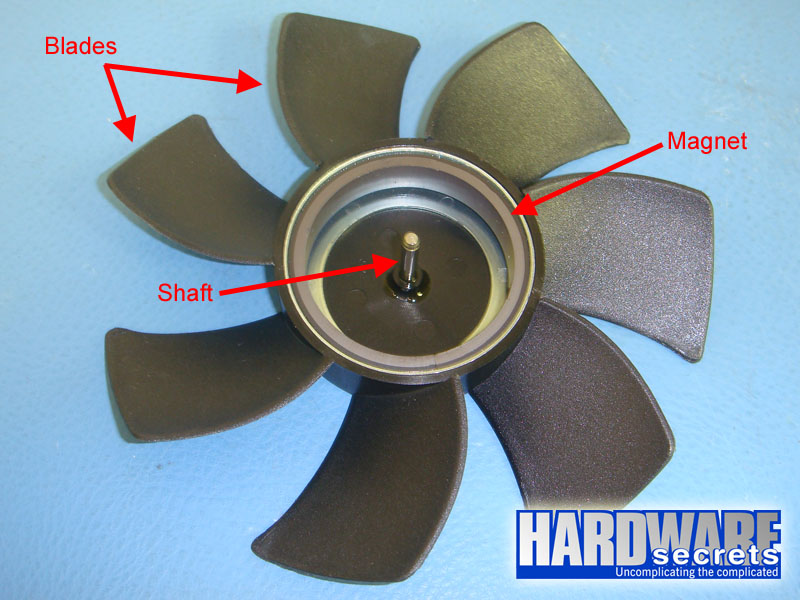

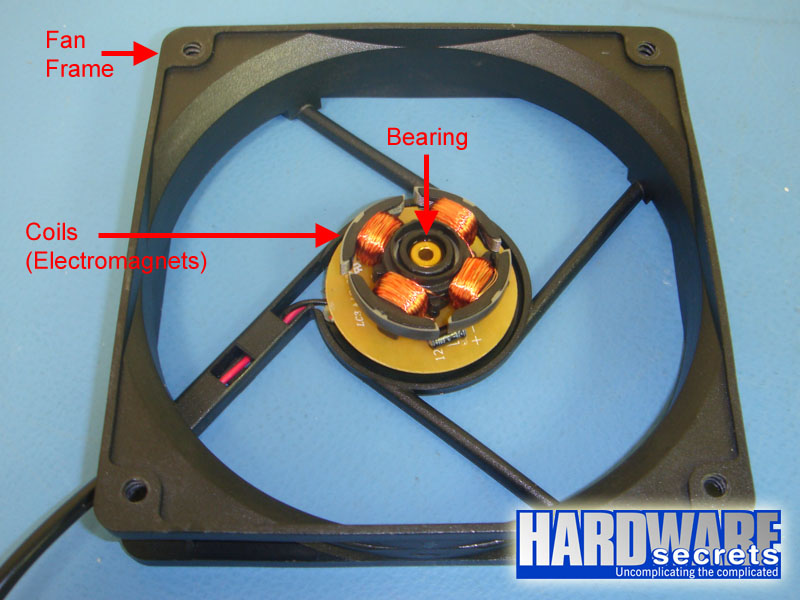

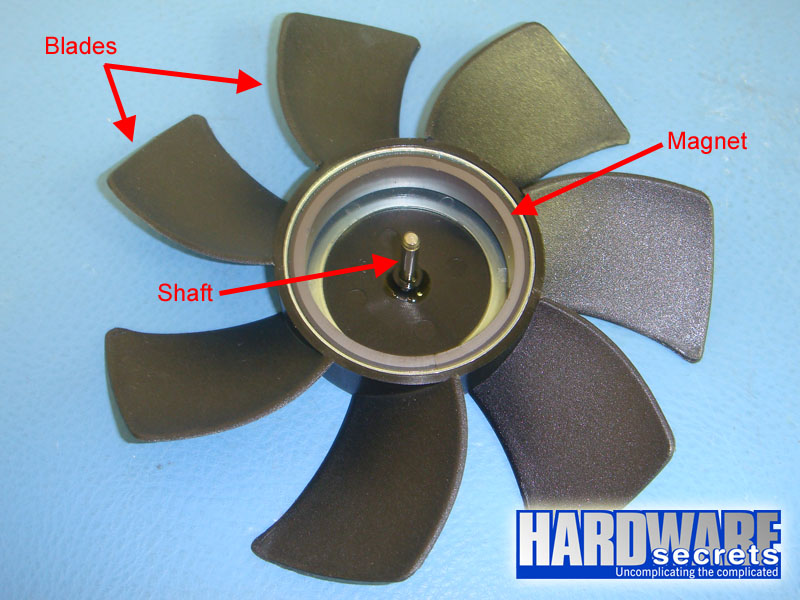

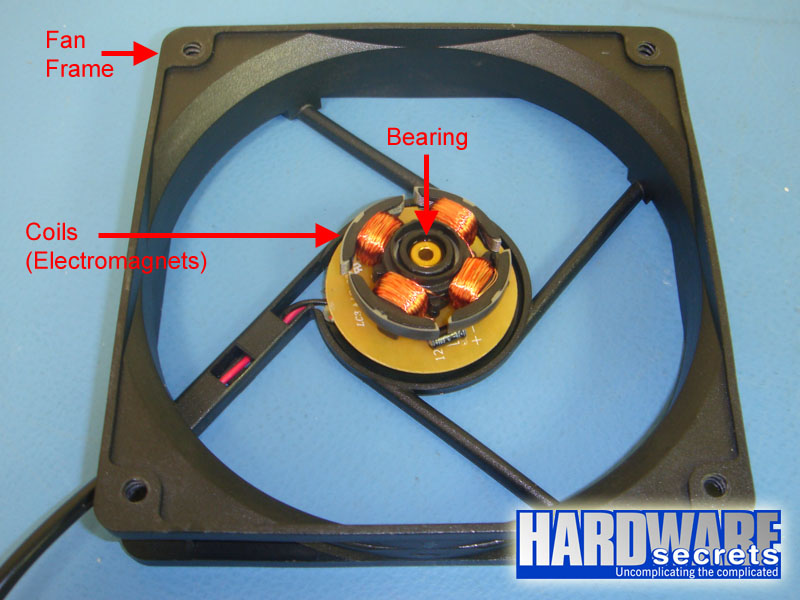

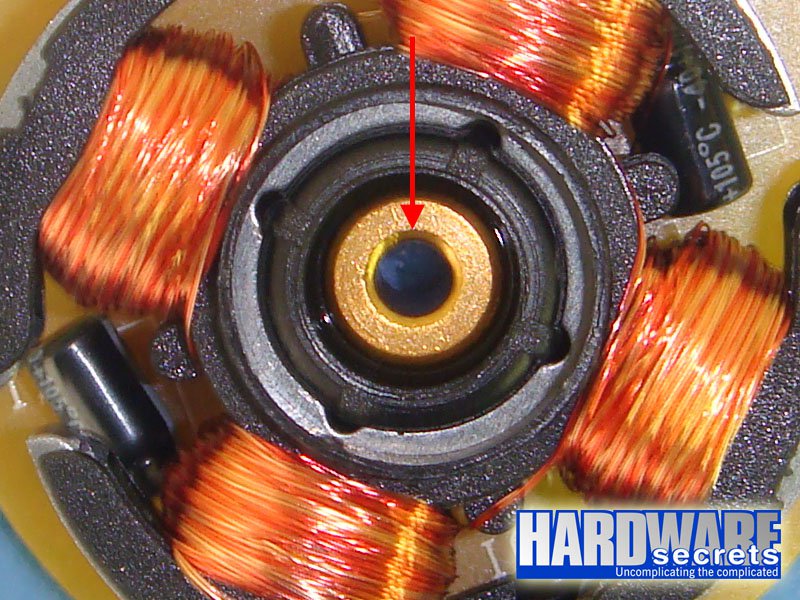

In the case of computer fans, the magnet is attached to the blade assembly, and this piece has the shaft attached to it (this whole piece is called the rotor). The rotor moves when mounted in the fan frame, also called the stator. The electromagnets are installed in the stator, and they don’t move. In the middle of the piece where the coils are attached to them is a hole where the shaft attached to the blade assembly is installed. This hole is the famous bearing that we will discuss in detail later.

Figure 3: Blade assembly (rotor)

Figure 4: Fan frame (stator)

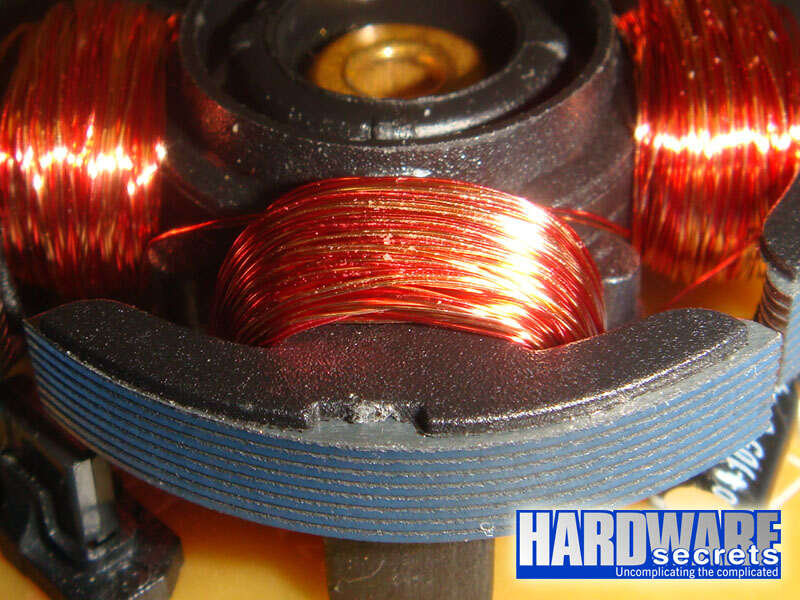

Brushless motors can be constructed with several coils and computer fans usually have eight of them. Inside a computer fan you can easily spot four T-shaped metallic “arms” or “teeth,” with each piece having two coils attached, usually one using red copper wire and the other using standard copper wire (see Figure 5).

Figure 5: Each T-shaped piece has two coils

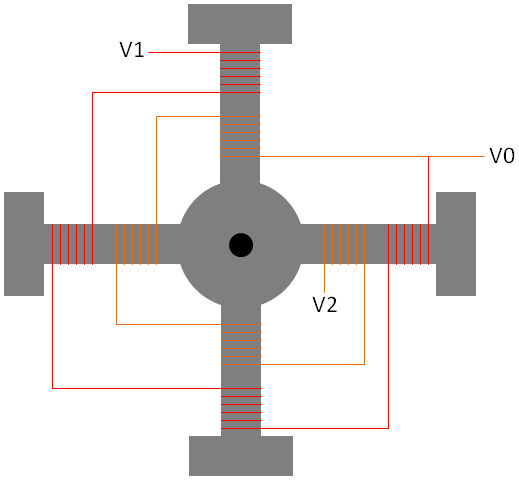

These coils are connected as shown in Figure 6. In our example, V0 is the common wire for both sets of coils, V1 is the wire for energizing the red-wire coils and V2 is the wire for energizing the bare-wire coils.

Figure 6: How the coils are connected

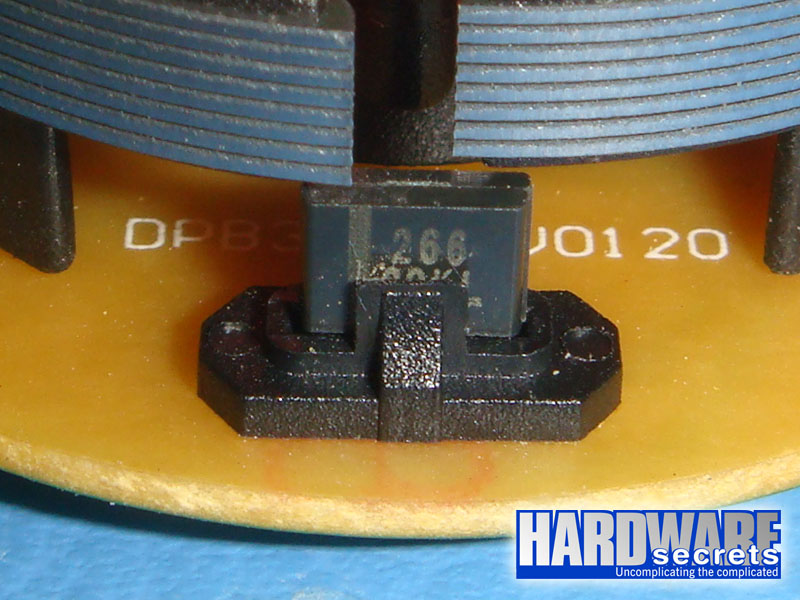

An integrated circuit present on the fan printed circuit board controls the coils. It will energize the coils in a way that will keep the motor spinning. In other words, this integrated circuit will change the magnetic field generated by the coils in such a way that the they will repel the magnet present in the rotor, causing it to spin and keeping it spinning.

Figure 7: Integrated circuit

Basic brushless fans will have only two wires. Optionally, brushless fans can have a monitoring circuit to feed the computer motherboard with a waveform that represents the speed of the rotor. This way you can monitor the speed of the fan through the motherboard setup or a fan monitoring program. This circuit is available through a third wire, so fans with three wires coming out of them have this sensor. The addition of this circuit makes the fan a little bit more expensive, of course.

Fancier fans can have a fourth wire that is connected to the integrated circuit of the fan to control the speed of the fan, through a technique called pulse width modulation

(PWM). If this wire is present, the speed of the fan will be controlled by the computer motherboard, and you can set your computer to change the speed of the fan depending on the temperature read by a given thermal sensor located inside the computer. This kind of fan is more expensive than fans that have only a monitoring wire, of course.

It is important to understand that you can control the speed of the fan by reducing the voltage, accomplished by installing a potentiometer or a fan speed controller. Note that in this case you, the user, is the one that is controlling the speed of the fan, rather than what happens with PWM fans, where it is the computer that controls the speed of the fan.

Of course this is an oversimplification of how brushless fans work. There are a lot more details about brushless motors, but we decided to focus exclusively on their use as computer fans.

The advantages of brushless motors over motors with brushes is quite obvious: they produce less noise, they don’t produce sparks, and they are more reliable.

[nextpage title=”The Sleeve Bearing”]

Now that you know how computer fans work, let’s examine the component that is the source of a lot of doubts, the bearing.

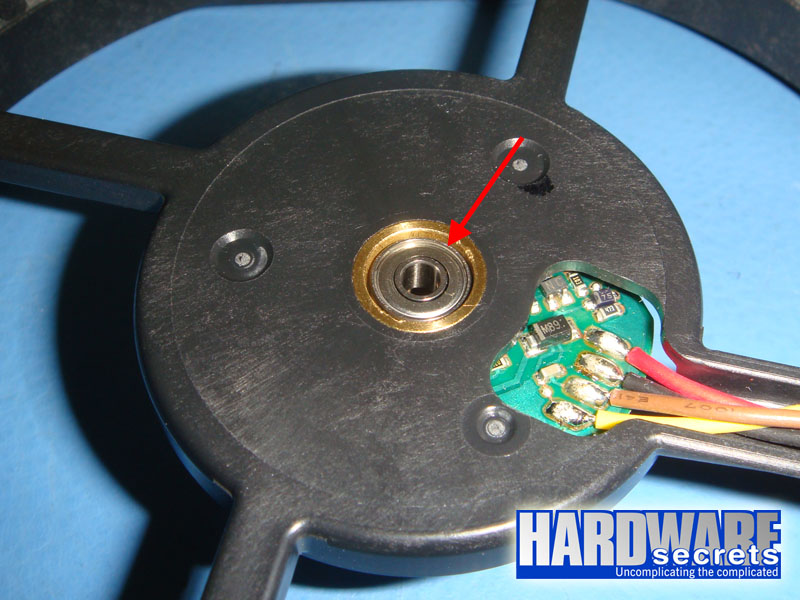

The bearing is the component that allows the rotor shaft to spin, the point of contact between the rotor and the stator. It is located exactly in the middle of the stator, as already shown in Figure 4.

The type of bearing used will tell us basically two parameters, the amount of noise produced by the fan and its expected life-span.

There are two basic kinds of bearings available: sleeve bearings and ball bearings.

The sleeve bearing is the most basic kind of bearing available. It is basically a lubricated tube where the rotor shaft will be inserted in.

Figure 8: Sleeve bearing

People say that fans using sleeve bearing are quieter than ball-bearing fans, but this is only partially true. When the fan is brand new, this is true. But as the fan ages and the oil or grease that is available inside the tube starts drying up, this kind of fan starts getting noisier than ball-bearing fans.

The drying up of the lubricant (oil or grease) is an inevitable process and when there is not enough lubricant inside the tube, the fan will fail. Because of that, sleeve-bearing fans have the lowest life-span among computer fans. On the other hand, they are the most inexpensive type of fan.

It is important to understand that the life-span depends on the operating temperature of the fan, since with increase in temperature, the lubricant tends to evaporate faster.

Below we show a table with the expected life-span of sleeve-bearing fans depending on the room temperature (source: WILLIAMS, Melody. Ball vs sleeve: a comparison in bearing performance. Chatsworth, NMB Technologies Corporation). Most manufacturers, however, rate sleeve-bearing fans with an expected life-span of 30,000 hours at 40° C.

| Temperature | Expected Life-Span |

| 25° C | 80,000 hours |

| 40° C | 52,000 hours |

| 50° C | 40,000 hours |

| 60°C | 30,000 hours |

A drawback observed in sleeve-bearing fans is that they are not designed to be mounted withe shaft horizontal, because by installing it horizontally, the oil inside the tube will all go to one of the sides of the shaft. Therefore for best performance, sleeve-bearing fans must be mounted with the shaft vertical so the oil inside the bearing is always spread more or less evenly. Unfortunately most power supply and case manufacturers don’t follow this recommendation, which can decrease the fan life-span.

[nextpage title=”The Ball Bearing”]

The ball bearing ring is a sealed hardware piece with small metallic balls inside (see Figure 9). Although open ball bearing rings do exist, they are not used in computer fans. This is the same kind of bearing used on roller blades and skate boards, for example.

Figure 9: The ball bearing ring

Figure 10: The ball bearing ring

Since it is a closed component, the lubricating material (usually grease) present inside evaporates at a slower pace compared to the sleeve bearing, making fans based on this component last longer. For example, at 50° C the expected life-span of a sleeve-bearing fan is 40,000 hours, while the life-span of a ball-bearing fan under the same temperature is 63,000 hours, 57% longer!

As with sleeve bearings, the life-span of ball-bearing fans depends on the temperature, as seen in the table below (source: WILLIAMS, Melody. Ball vs sleeve: a comparison in bearing performance. Chatsworth, NMB Technologies Corporation). Most fan manufacturers, however, rate ball-bearing fans with an expected life-span of 50,000 hours at 40° C.

| Temperature | Expected Life-Span |

| 25° C | 95,000 hours |

| 40° C | 75,000 hours |

| 50° C | 63,000 hours |

| 60° C | 54,000 hours |

Ball-bearing fans can be noisier than sleeve-bearing fans when both are new, but, as explained in the previous page, as they age, the noise level produced by sleeve-bearing fans increases and they become noisier than ball-bearing models.

Some fans can use two ball bearing rings instead of just one; they are called dual ball-bearing fans or 2BB (“two ball bearings”). In this case a bearing is placed at each side of the stator. Fans that use only one ball bearing are also known as 1B1S (“one ball and one sleeve bearings”), because, while a ball bearing is used at one side of the stator, on the other side, a sleeve bearing is still used to hold the shaft in place.

As opposed to sleeve-bearing fans, they can be mounted vertically or horizontally, since the lubricating material is locked inside the bearing.

As you may have guessed, fans with one ball bearing are more expensive than sleeve bearing fans, while fans with two ball bearings are more expensive than fans with one ball bearing.

[nextpage title=”Other Types of Bearings”]

Manufacturers are always trying to get a bearing that can last longer and produce less noise. Most of the other kinds of bearings are modifications of the sleeve bearing design to achieve bearings that are cheaper than ball bearings, but last longer than sleeve bearings.

It is very important to understand that sometimes a “new” kind of bearing is used by only a specific manufacturer, and that is why you may not see information about a specific bearing type being listed below.

Rifle Bearings

The rifle bearing is a modified sleeve bearing with a spiral groove inside the tube that pumps oil from a reservoir. This groove makes the tube always “wet,” allowing the fan to be installed horizontally, unlik

e sleeve-bearing fans. The life-span of this kind of bearings is between that of sleeve bearings and ball bearings.

Fluid Dynamic Bearings

Also known as hydro dynamic bearings, this is a modified sleeve bearing where the shaft doesn’t touch the tube on the stator; the tube is filled with oil and therefore the shaft spins inside this oil compartment. According to Jaro Thermal, fluid-bearing fans have a life expectancy of 60,000 hours at 40° C. As the shaft will always be “wet,” this kind of fan can be mounted horizontally.Magnetic Bearings

Magnetic bearings, also called magnetic levitation bearings or simply maglev, make the rotor shaft “float” inside the stator tube, without touching it, through the use of magnetic force. This way, no lubricant is necessary. Since there is no physical contact between the shaft and the stator, the noise level produced by this kind of bearings is the lowest possible. According to Sunon, this kind of fan has a life-span of 50,000 hours at “room temperature” (which we assume is 25° C). A detailed explanation about this technology can be found here.Ceramic Bearings

Also called a hybrid bearing, it is a bearing ring that contains ceramic balls instead of steel balls.

Leave a Reply